Jiangsu Juming Chemical Technology Co., Ltd.

Product Description

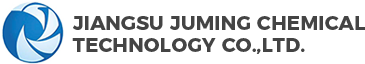

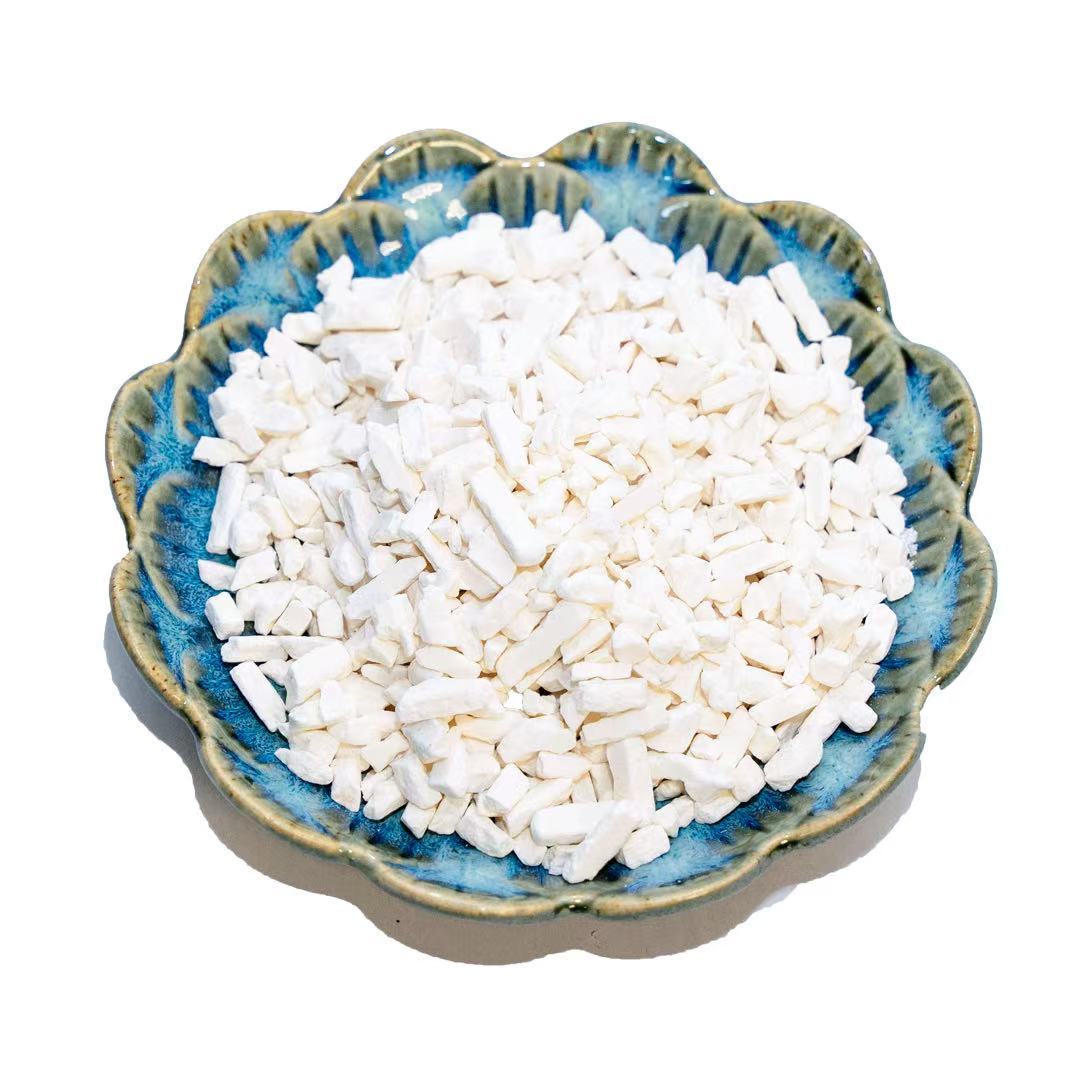

Coupling agent is a kind of material with two functional groups of different properties. The biggest characteristic is that its molecular structure is that the molecule contains two groups with different chemical properties. One is a group that is pro-inorganic, which is easy to react with the surface of the inorganic.The other is an organophilic group that can react chemically with synthetic resins or other polymers or form hydrogen bonds dissolved in them.Therefore, the coupling agent is called "molecular bridge" to improve the interface between inorganic and organic matter, so as to greatly improve the properties of composite materials, such as physical properties, electrical properties, thermal properties, optical properties, etc.Coupling agent used in rubber industry can improve the wear resistance and aging resistance of tire, rubber plate, rubber hose, rubber shoes and other products, and can reduce the amount of NR, so as to reduce the cost.Coupling agent on the role of composite materials is that it can react with certain groups on the surface of the reinforced material, and can react with matrix resin, between reinforcing materials and resin matrix in the formation of an interface layer, interface layer can pass stress, so as to enhance the bonding strength between the reinforcing materials and resin, which improves the performance of composite material, at the same time can also prevent other medium to permeate interface,The improvement of interface state is conducive to aging resistance, stress resistance and electrical insulation performance of products.

Uses:

Adhesives and coatings: improve wet adhesive force, weather resistance, improve pigment dispersion, improve wear resistance and resin crosslinking.

Casting: to improve the strength of resin sand.In order to achieve high, low gas.

Rubber: improve the mechanical strength, wear resistance, wet electrical properties and rheological properties of products.

Sealant: improve the wet adhesive force, improve the dispersion of packing, wear resistance of products.

Textiles: make the textiles soft and plump, improve its water resistance, and the adhesion of dyes.

Printing ink: to improve the wettability of adhesive force.

Filler surface treatment: in the resin to improve the compatibility of the filler and resin, wettability, dispersion.

PREVIOUS:

NEXT:

Coupling reagent

We have a professional export team and our brushes are exported to European and American countries. We can do OEM and ODM services. We have a brush design team that develops and designs new brushes every year.

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Product Description

Coupling agent is a kind of material with two functional groups of different properties. The biggest characteristic is that its molecular structure is that the molecule contains two groups with different chemical properties. One is a group that is pro-inorganic, which is easy to react with the surface of the inorganic.The other is an organophilic group that can react chemically with synthetic resins or other polymers or form hydrogen bonds dissolved in them.Therefore, the coupling agent is called "molecular bridge" to improve the interface between inorganic and organic matter, so as to greatly improve the properties of composite materials, such as physical properties, electrical properties, thermal properties, optical properties, etc.Coupling agent used in rubber industry can improve the wear resistance and aging resistance of tire, rubber plate, rubber hose, rubber shoes and other products, and can reduce the amount of NR, so as to reduce the cost.Coupling agent on the role of composite materials is that it can react with certain groups on the surface of the reinforced material, and can react with matrix resin, between reinforcing materials and resin matrix in the formation of an interface layer, interface layer can pass stress, so as to enhance the bonding strength between the reinforcing materials and resin, which improves the performance of composite material, at the same time can also prevent other medium to permeate interface,The improvement of interface state is conducive to aging resistance, stress resistance and electrical insulation performance of products.

Uses:

Adhesives and coatings: improve wet adhesive force, weather resistance, improve pigment dispersion, improve wear resistance and resin crosslinking.

Casting: to improve the strength of resin sand.In order to achieve high, low gas.

Rubber: improve the mechanical strength, wear resistance, wet electrical properties and rheological properties of products.

Sealant: improve the wet adhesive force, improve the dispersion of packing, wear resistance of products.

Textiles: make the textiles soft and plump, improve its water resistance, and the adhesion of dyes.

Printing ink: to improve the wettability of adhesive force.

Filler surface treatment: in the resin to improve the compatibility of the filler and resin, wettability, dispersion.

Get Product Information For Free

Note: Please leave your email address, our professionals will contact you as soon as possible!

E-mail:

Service Hotline: