Jiangsu Juming Chemical Technology Co., Ltd.

Product Description

Glycidyl methacrylate Basic information

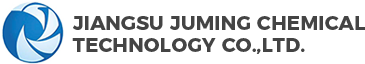

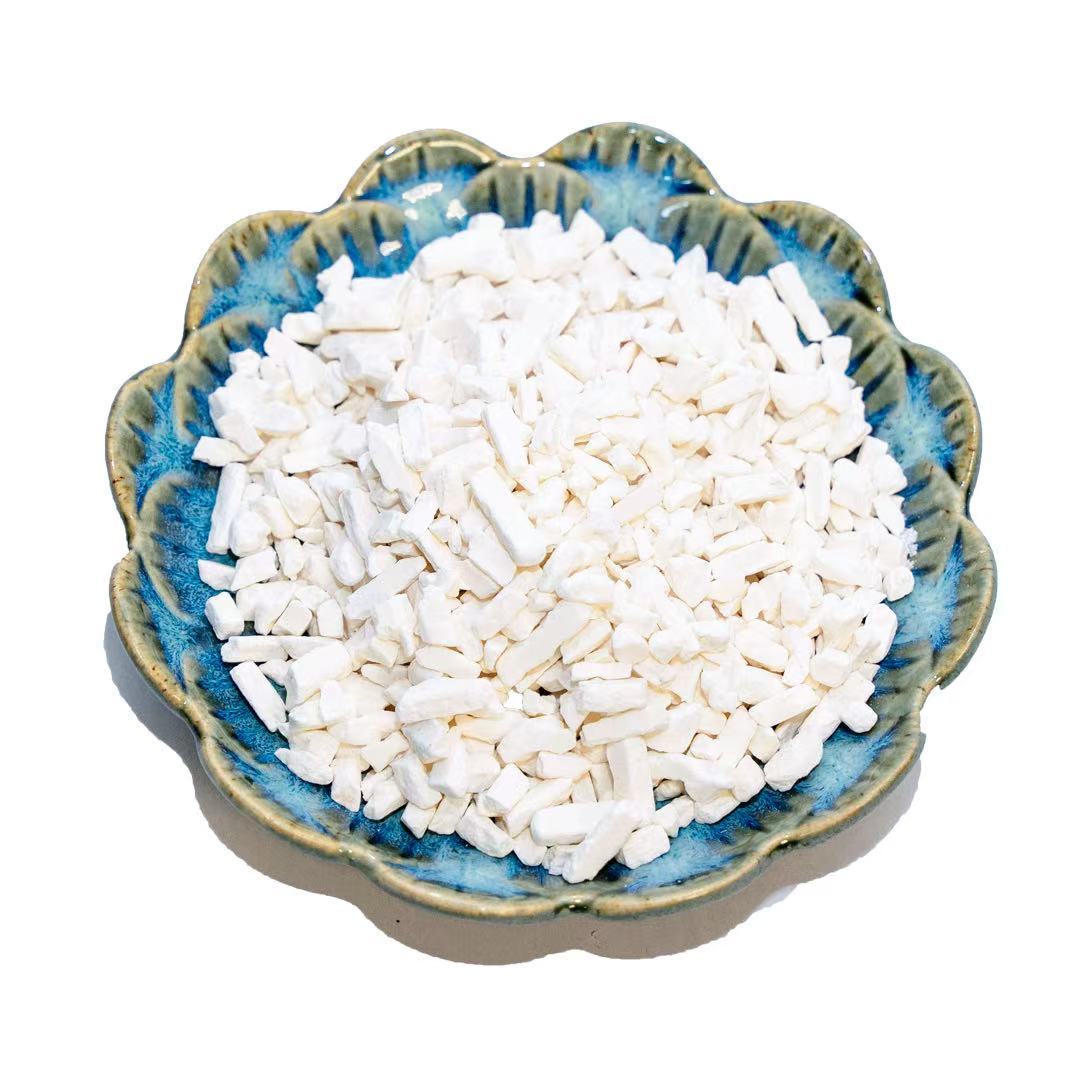

Product Name: Glycidyl methacrylate

CAS: 106-91-2

MF: C7H10O3

MW: 142.15

Glycidyl methacrylate Chemical Properties

Melting point: -52°C

Boiling point: 189 °C(lit.)

density: 1.075 g/mL at 20 °C

vapor pressure: 4.2hPa at 25℃

Glycidyl methacrylate Usage

Glycidyl methacrylate (GMA) is a common monomer used in the creation of epoxy resins. It is used to provide epoxy functionalization to polyolefins and other acrylate resins.

Glycidyl methacrylate is used in the production of polymer coatings and finishes, adhesives, plastics and elastomers.

Glycidyl methacrylate dextran has been reported to be used as a biocompatible hydrogel. In situ polymerization of GMA with trimethylolpropane trimethacrylate to form macroporous sorbents has also been reported. GMA may also be grafted onto polypropylene.

PREVIOUS:

Glycidyl methacrylate(GMA)

We have a professional export team and our brushes are exported to European and American countries. We can do OEM and ODM services. We have a brush design team that develops and designs new brushes every year.

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Product Description

Glycidyl methacrylate Basic information

Product Name: Glycidyl methacrylate

CAS: 106-91-2

MF: C7H10O3

MW: 142.15

Glycidyl methacrylate Chemical Properties

Melting point: -52°C

Boiling point: 189 °C(lit.)

density: 1.075 g/mL at 20 °C

vapor pressure: 4.2hPa at 25℃

Glycidyl methacrylate Usage

Glycidyl methacrylate (GMA) is a common monomer used in the creation of epoxy resins. It is used to provide epoxy functionalization to polyolefins and other acrylate resins.

Glycidyl methacrylate is used in the production of polymer coatings and finishes, adhesives, plastics and elastomers.

Glycidyl methacrylate dextran has been reported to be used as a biocompatible hydrogel. In situ polymerization of GMA with trimethylolpropane trimethacrylate to form macroporous sorbents has also been reported. GMA may also be grafted onto polypropylene.

Get Product Information For Free

Note: Please leave your email address, our professionals will contact you as soon as possible!

E-mail:

Service Hotline: