Jiangsu Juming Chemical Technology Co., Ltd.

Product Description

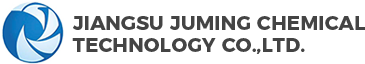

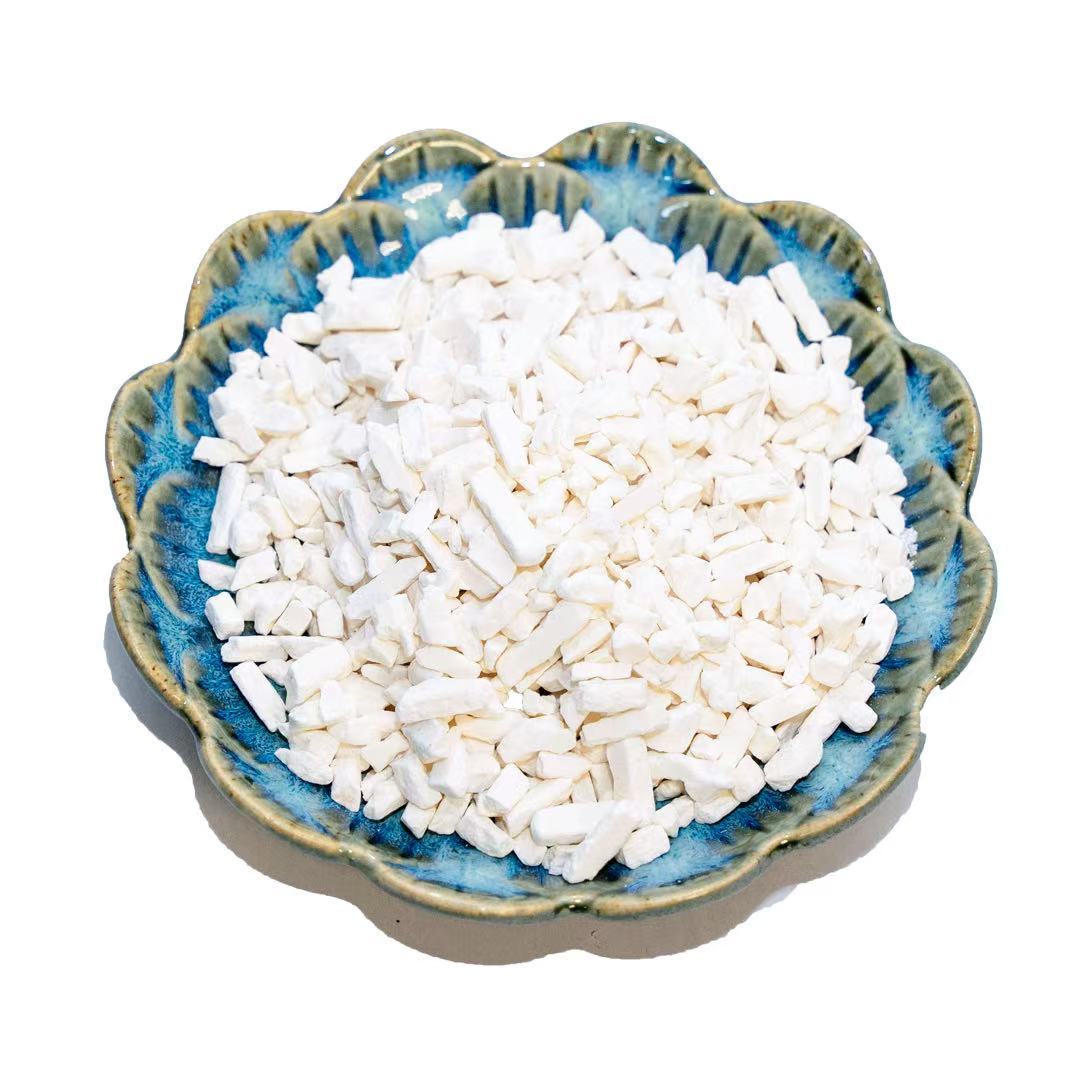

Photoinitiator (PI) is the key component of UV curing materials, which plays a decisive role in the speed of UV curing. Photoinitiator is a kind of material which can absorb radiation energy and produce active intermediates (free radicals or cations) with the ability of initiating polymerization. Photoinitiators can be divided into ultraviolet initiators (absorption ultraviolet region 250-420 nm) and visible initiators (absorption visible region 400-700 nm) due to different absorption radiation energy. Photoinitiators can be divided into two types: free radical photoinitiators and cationic photoinitiators. The free radical photoinitiators can be divided into two types: pyrolysis photoinitiators and hydrogen abstraction photoinitiators because of the different mechanism of producing free radicals. At present, the UV curing technology is mainly UV curing, and the photoinitiator used is UV initiator.

Advantages:

(1) Cheap and easy to synthesize;

(2) Nontoxic and tasteless;

(3) High molar extinction coefficient;

(4) High jump efficiency;

(5) High initiation efficiency.

(6) Good stability, easy to store for a long time;

Use:

Photoinitiator is mainly used for screen printing ink, lithographic printing ink, flexo printing ink, wood coating. It can be widely used in all kinds of coatings, with no yellowing, low post polymerization effect and no residue. It can also be used for transparent coating, especially for products with low odor requirements. For acrylic system, especially for colored system, it is usually used with amine or acrylamide, and combined with other photoinitiators to achieve complete curing of the system. It is especially suitable for curing low yellowing, white system and thick film.It can also be used in colored UV curable plastic coatings. Because of its excellent performance and efficient production, UV coatings have been widely used in the plastic shell of various electronic and household appliances. However, the deep curing of UV coating after coloring is not good, resulting in poor film adhesion and poor dispersion of UV resin to pigments, which seriously affects the appearance of the coating, Therefore, the traditional construction process is to paint solvent based color primer for coloring, and then paint UV varnish after baking to improve the physical properties of the film surface.

PREVIOUS:

NEXT:

Photoinitiator

We have a professional export team and our brushes are exported to European and American countries. We can do OEM and ODM services. We have a brush design team that develops and designs new brushes every year.

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Product Description

Photoinitiator (PI) is the key component of UV curing materials, which plays a decisive role in the speed of UV curing. Photoinitiator is a kind of material which can absorb radiation energy and produce active intermediates (free radicals or cations) with the ability of initiating polymerization. Photoinitiators can be divided into ultraviolet initiators (absorption ultraviolet region 250-420 nm) and visible initiators (absorption visible region 400-700 nm) due to different absorption radiation energy. Photoinitiators can be divided into two types: free radical photoinitiators and cationic photoinitiators. The free radical photoinitiators can be divided into two types: pyrolysis photoinitiators and hydrogen abstraction photoinitiators because of the different mechanism of producing free radicals. At present, the UV curing technology is mainly UV curing, and the photoinitiator used is UV initiator.

Advantages:

(1) Cheap and easy to synthesize;

(2) Nontoxic and tasteless;

(3) High molar extinction coefficient;

(4) High jump efficiency;

(5) High initiation efficiency.

(6) Good stability, easy to store for a long time;

Use:

Photoinitiator is mainly used for screen printing ink, lithographic printing ink, flexo printing ink, wood coating. It can be widely used in all kinds of coatings, with no yellowing, low post polymerization effect and no residue. It can also be used for transparent coating, especially for products with low odor requirements. For acrylic system, especially for colored system, it is usually used with amine or acrylamide, and combined with other photoinitiators to achieve complete curing of the system. It is especially suitable for curing low yellowing, white system and thick film.It can also be used in colored UV curable plastic coatings. Because of its excellent performance and efficient production, UV coatings have been widely used in the plastic shell of various electronic and household appliances. However, the deep curing of UV coating after coloring is not good, resulting in poor film adhesion and poor dispersion of UV resin to pigments, which seriously affects the appearance of the coating, Therefore, the traditional construction process is to paint solvent based color primer for coloring, and then paint UV varnish after baking to improve the physical properties of the film surface.

Get Product Information For Free

Note: Please leave your email address, our professionals will contact you as soon as possible!

E-mail:

Service Hotline: